VIDEO: Introduction to Earth Tools

PDF Text document: The history of Italian walk-behind tractors in North America (and a history of Earth Tools as well)–A perspective by Joel Dufour, Earth Tools owner

In 1977, my father, Victor Dufour, started a home-based small equipment business in Southern Indiana called D & D Enterprises. One of the three equipment lines the business began with was BCS walk-behind tractors (marketed at that time as “Mainline” brand machines through an importer in Ohio). My Dad was impressed with the quality and versatility of the product, and besides, we needed a good tiller and sickle bar mower! We used a BCS 715 8hp gas model (equivalent to the 722 of today) to start a small farm, on which we grew the majority of the food to supply our family (Mom, Dad & 7 kids!) and sold organic produce to restaurants for extra income. This machine broke 5 acres of sod, cultivated, mowed a 17-acre hayfield, cleared snow and ran a sprayer pump. We put 1700 hours on it in 6 years and spent about $120 in maintenance (mostly tiller tines!). We then put a new engine on that 715 and sold it (it is still in service; the transmission has never been serviced except for an occasional oil change) and we graduated to a model 735 (roughly the equivalent of the 853 today) with a 10hp Lombardini diesel engine equipped with wind-the-rope-on-the-pulley-and-PULL start. We added a lawn mower implement and a 5-foot Hayrake/tedder to the tractor’s list of chores and put about 2500 hours on this unit over the next 5 years. The workload was great enough (and the labor pool large enough, with all those kids!) that we finally started using two walk-behind tractors simultaneously around 1988 by adding a BCS 604 (a front-PTO-only machine, for all our mowing/hayraking applications) to the workforce.

Joel's family in 2022: Natalie (19), Chris, Joel and Sophie (15)

All this time, our small equipment business was growing too. Having tons of first-hand experience with the equipment enabled Dad to be very successful selling BCS, and we quickly became the largest dealer in Indiana. Dad’s business was also expanding by selling & servicing more equipment lines - mostly in the way of chain saws and logging supplies, since Southern Indiana is a fairly large hardwood-lumber-producing area. Even though our business was located “out in the sticks” 9 miles from the nearest town and 7 miles to the nearest highway, our business attracted customers from far & wide, eventually putting the shops ‘in town’ out of business. Why? 1. We sold top-quality products at reasonable prices. 2. We stood behind those products and took care of our customers. 3. Service, Service, Service.

Dad taught me that to repair something, you first have to understand how it works, and then figure out why it broke and try to fix it so it didn’t fail again. We were constantly coming up with improvements for various products we sold. Our “return” rate (equipment that came back in after we had worked on it, because it wasn’t repaired properly) was staggeringly low…this was, I’m sure, the main reason our reputation kept attracting customers from further & further away. I have carried this philosophy with me: If something is worth doing, it’s worth doing RIGHT.

I always gravitated toward the walk-behind tractors within Dad’s business. I had started working in Dad’s shop in 1980 (when I was ten years old), and by sixteen I was doing all the BCS sales & service in our family business. By eighteen I was general service manager for all equipment lines, managing up to 4 mechanics (2 were younger brothers…does that count?)

In 1993, I wanted to ‘spread my wings’ and have a business of my own. Dad said “Well, you might as well take over the BCS franchise… you’ve been doing it so long now that I don’t know how to sell them anymore… I just use ‘em!”

And so, in late 1993, my first business, Earth Tools & Goods was founded; my first shop was on a rented piece of land about 7 miles from Dad’s farm in Indiana. I bought a couple of used semi-trailers, removed the axles and converted them into a shop. My product offerings were BCS walk-behind tractors & implements and Dewit garden tools (branded at the time “De Van Koek”), which I had gotten into mainly to purchase a set of really good tools for myself! I continued to raise most of my own food and kept the principles learned in Dad’s business: Treat your customers like you want to be treated, offer the best products you can find and keep prices reasonable by keeping overhead low (hence the semi-trailers) until you have saved enough to pay for improvements. Going in debt was a no-no, and although I made it through the first winter on my own only by cashing in all the spare change I had saved up in tin cans as a kid to pay the bills, I stuck to it. My business grew, and in late 1994 I met the woman who would change my life (hey-isn’t that too corny to put in here?). In late 1997 we were married, and in 1998 I moved to her family’s land in central Kentucky, selling my business in Indiana to a friend. With walk-behind tractors still in my blood, I took on the then-defunct BCS franchise in this part of Kentucky and started Earth Tools Inc in a 16’ x 24’ shed I built out of salvaged barn lumber. My wife and I lived in a 10’x 15’ cabin for 4 years while we built our Earth-bermed, slip-formed-fieldstone & concrete-retaining-wall, partial timber-framed (with salvaged lumber), partial straw-bale, partial cordwood, passive-solar-assist, off-the-grid house (whew!) on the side while I ran the business.

AIN'T they just adorable? Natalie (19) and Sophie

(15) goofing around in the daffodil patch

We ran out of room in my little shop (and the neighbor’s shed, and my brother-in-law’s barn) after 3 years or so, close to the same time that I found I just couldn’t keep up with the growing workload. So I took on a partner: Shannon Kington. Shannon and his wife Carol had purchased equipment from me to run their small farm in Southern Kentucky, and were so thrilled with the way the equipment was constructed (Shannon had a lot of experience in machining and metalworking, so he recognized the quality right away) and the way it performed that they wanted to get into trying to sell it right away in their community. Unfortunately their local area was fairly economically depressed, so they couldn’t find buyers there…on the other hand, I was struggling to keep up with my growing business and needed help. So they moved to Owenton and joined the business in 2002. It was Shannon & Carol who convinced me to put up a website, which eventually grew the business beyond what I’d ever thought possible. We leased a barn and run-down little house on a neighbor’s property to move the business into in 2002, which approximately quadrupled our operating space. Shannon has since retired (he was 62 when he joined Earth Tools) and we have continued to grow our staff as our business has flourished; we currently have 14 full-time employees (besides myself). Of course, we had to build bigger facilities…

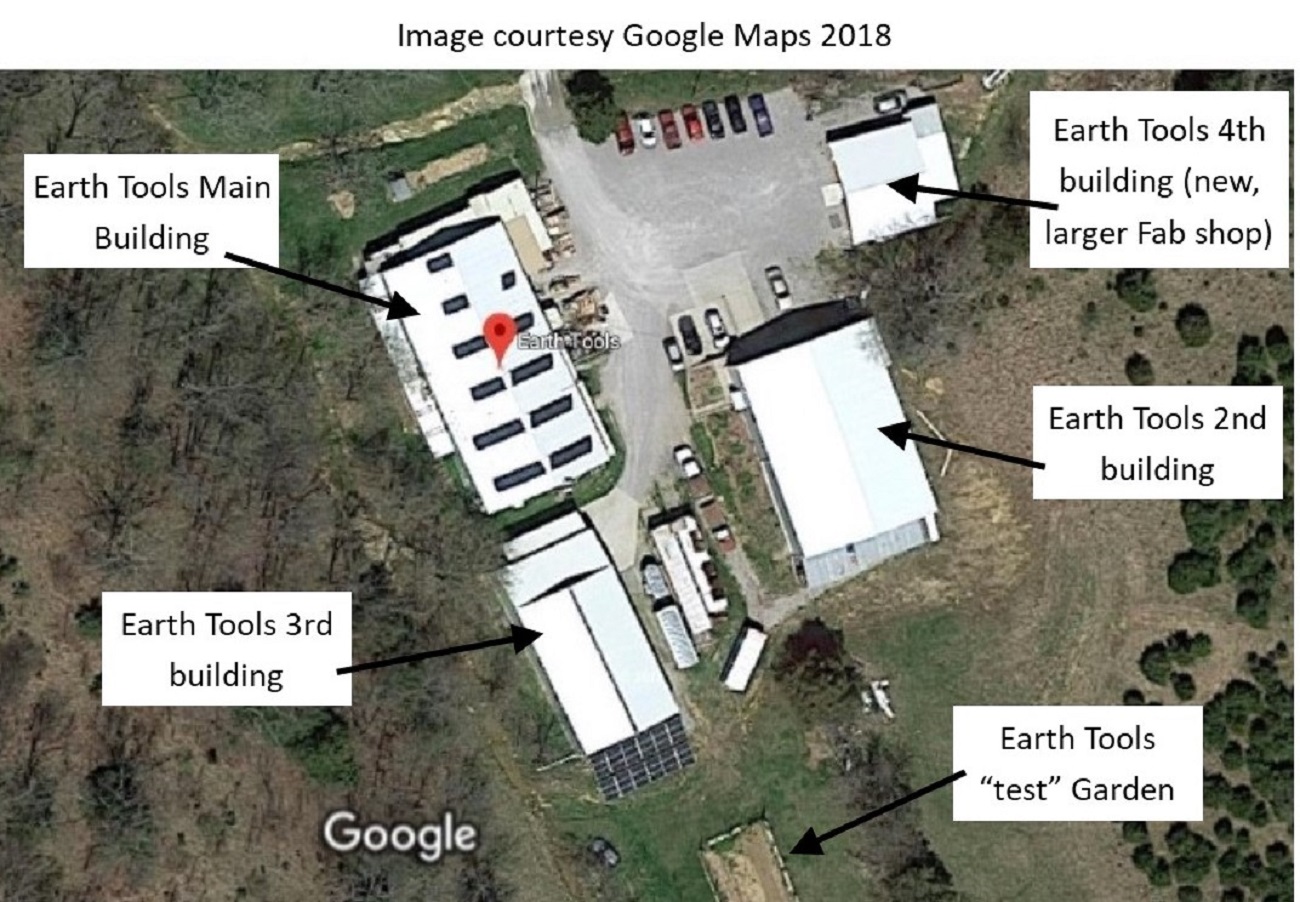

In 2006 we began construction of a new 7500 square foot building, which was finally completed in 2008. We incorporated several energy-efficient/green features into the building design. Click here for a full list of our “green” practices. (We have added several more buildings over the years…see photos at the bottom of page. We are now at nearly 20,000 square feet of space…dedicated to walk-behind tractors!)

As the business has grown, it has been an honor and privilege to have the wherewithal to donate a portion of our profits to causes and organizations we believe in… Click Here for a list of efforts we support.

Our family has grown as well; in 2003 Natalie was born, and in 2007 Sophie joined us (Sophie was a home-birth, something I now strongly recommend). The 900 square-foot house we built is getting tighter, but shoot - by Global standards, we have PLENTY of space! We grow roughly a 1/3 acre organic garden…nothing like the market farm I grew up with, but enough to provide much of our food. I LOVE gardening and if I had time I would do more…but I spend most of my time taking care of the equipment needs of market gardeners and homesteaders! I guess the mechanic/salesman in me slightly outweighs the gardener….

We currently own a 1995 model BCS 850 with a 12hp gas engine (one of the ACME Italian engines; nearly the last one to come into the USA) on it, and this fulfills most of the equipment needs we have on our 180-acre property (to be fair: Most of our property is woods): It works the garden, mows the lawn (actually, I do more ‘gardening’ with the lawn-mower implement than anything else: all the grass clippings from the lawn go directly on the garden as mulch, acting as a weed barrier, moisture retainer, organic-matter addition and instant nitrogen boost), runs a brush mower, chipper/shredder, dozer blade for snow and gravel driveway maintenance and digs our potatoes with a root digger plow. We did pick up a second machine (used)…an old BCS 735, which I got because it was equipped with a rare (rare on a BCS, anyway) synchronized PTO unit and coupled with a driven-wheel trailer, making it a 4-wheel-drive utility vehicle that will carry a ton. We call this rig “The Blue Mule” and basically it is our farm truck. (Currently, only one of the Grillo brand tractors we sell still offers this option. BCS no longer produces a synchronized PTO unit.) The only other power equipment I own is a chain saw and a weed-eater.

Joel with an 853 diesel and 31" brush mower.

As this Country, and indeed the World, comes to grips with the resource-extraction limits, pollution limits, and the true economic realities of the present time, this type of small-scale, highly efficient, high-quality, multi-purpose equipment is only going to make more sense. I believe we need a food supply system in this Country (and everywhere) based on locally-grown food, not based on cheap petroleum (which is NOT cheap any more!) and its ability to get food to the consumer from where in can be produced with the cheapest labor. This type of equipment enables very small-scale farms to operate profitably with relatively minimal investment in new, high-quality goods (compared to conventional 4-wheel farm tractors) and therefore I believe in what we’re doing and providing here. I enjoy working with the folks who are working to put this kind of food system in place. I enjoy, and commiserate with, the homeowner who is tired of the junk put out by most “lawn & garden” equipment manufacturers and wants something built well enough they can hand it down to the next generation.

So thanks for reading, and thanks for your business, if you choose to give it to us; whether it be a tractor and implements you purchase, a spare part to keep an old machine going - or just a darn good shovel or hoe.

Y’all take care,

(I learned that in Kentucky!)

Joel Dufour

BJ Duvall, Inventory / Parts

Since 2013

Stephany Keller, Parcel Shipping Manager

Since 2017

David Hosey, Sales Dept

2011-2018, 2022-present

Josh Lyons, Service Dept

Since 2021

Kenneth Bays, Service Manager

Since Jan. 2020

Dennis Berry, LTL Shipping, Parts, and Sales

Since 2010

Ellen Engelman, Sales Manager

Since 2017

Michaela Hart, Office Manager

Since 2020

Hunter Matthews, Blacksmith/Fabrication Dept

Since 2015

Sarah Barreto, Parcel Shipping Dept

Since 2021

Logan Ernst, Warehouse Manager

Since 2015

Andy McDonald, Director, Earth Tools Sustainable Systems Program (Apogee)

Since 2013

Kevin Talbert, Warehouse packing / shipping

Since 2018

Jason Collins, Warehouse assembly tech.

Since 2023

"The Guy Whose Fault It Is"...if something's wrong with your equipment, it's THIS guy's fault!!

Earth Tools crew with a few friends & family (Christmas Party 2022)

The shop-cat, Carl (or Carlos). We gave him a desk chair and everything, but we just can’t get any work out of him…

Oh, Stephany was in the chair already? No purrrroblem...

On second thought, I'll try a new chair...this one's got a pillow.

Carl at the window after we threw him outside for sleeping on the job... I mean, Carl, what do you expect, dude? 3 strikes and you're OUT!

We decided to give him another chance and let him work in the service department: This is Carl working on a Berta flail mower. He still doesn’t have the job done…(Yes, he lay down here of his own accord and went to sleep…this is NOT a "staged" photo!!)

Earth Tools Main Building (since 2007). Houses offices, parts, shipping, tractor assembly, and some warehousing. From 2002 to 2007, we operated out of an old barn for a warehouse and a run-down old house for an office. From 1998 to 2002, it was all in my little 16'x24' shop next to my house! Note the solar panel array on the roof...this was installed in 2011.

Earth Tools second building (completed March 2012) --This houses a metal fabrication shop, a new showroom, and LOTS of additional warehouse space.

Earth Tools 3rd building, completed July 2015 … More warehouse space!!

Solar PV additional 11.5KW array,

put in service January 2016. We are now 100% solar-powered!!

New Fabrication Shop, completed in 2018. (Hunter, our main fabrication guru, posing with welding helmet)

Because you never have enough space...Warehouse 4, completed in 2023. (This one does NOT show up on Google Earth yet...but it replaces the 2 semi-trailer bodies that used to be between WH2 and WH3)

Aerial shot showing the ET layout in rural Owen County KY as of late 2018.